Intergovernmental Panel on The Intergovernmental Panel on Climate Change (IPCC) has estimated that to compensate for global CO2 emissions from flat glass production, in 2021 300,000 km2 of forest land would be needed. This is approximately equal to the total area of Italy. Emissions could be significantly reduced if industries could reuse used windows.

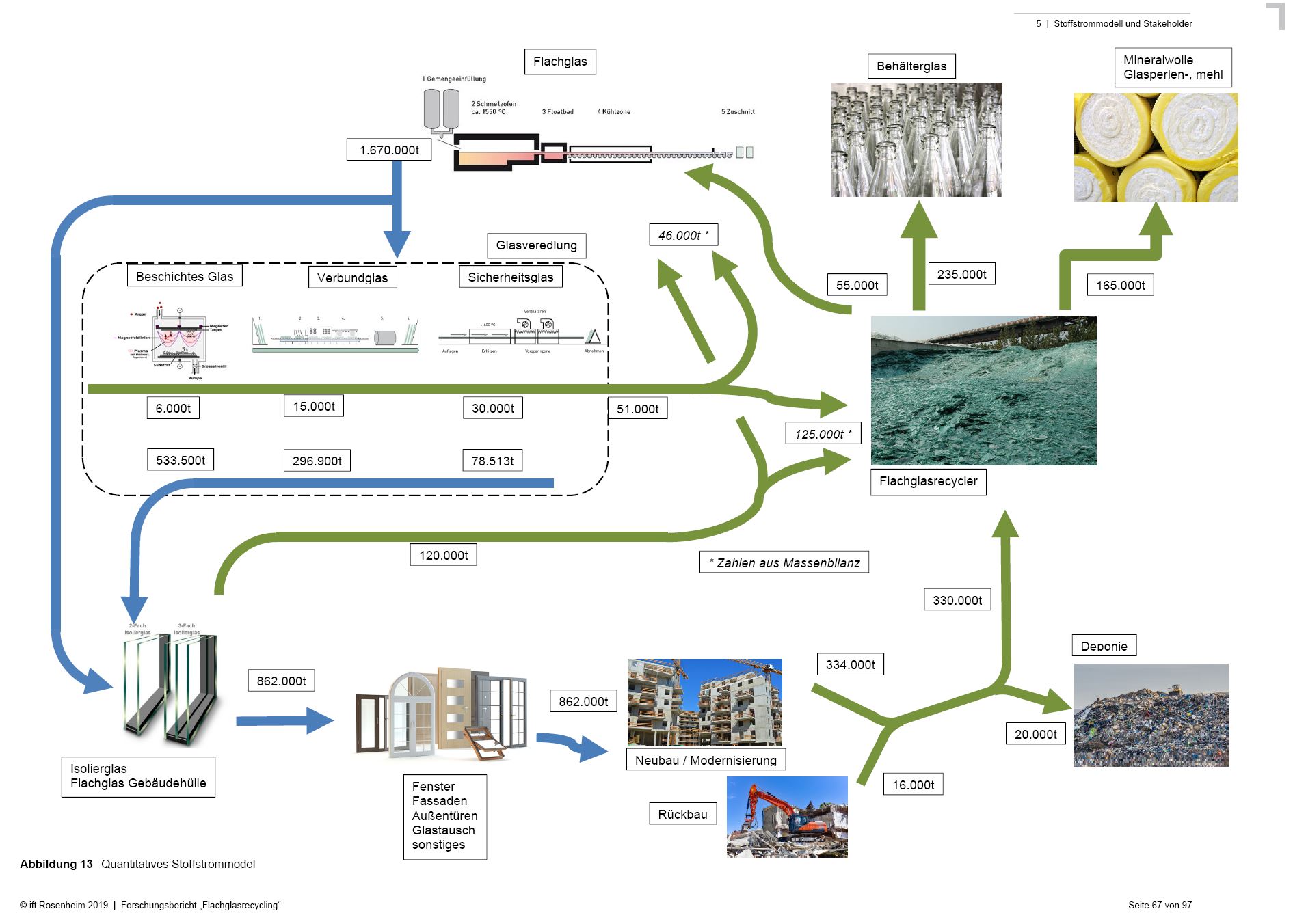

CO2 emissions per kilogram of flat glass made from recycled glass are 0.3 kg lower than for a batch of glass consisting only of virgin raw materials. The problem is that the amount of broken glass from demolition or dismantling of old buildings and renovations is too small and the recycled material streams do not flow sufficiently into the flat glass industry. Insulating glass and window glass are partly recycled, but only small amounts are recycled in a closed loop. 2019 study carried out by the German Flat Glass Association shows that only about 6% of the flat glass produced that leaves the manufacturer returns to the melting furnace and becomes flat glass again.

When a building reaches the end of its useful life, reusable materials are often still handed over to recyclers as construction debris. The situation is better in the case of deconstruction of buildings rather than demolition – the construction process is practically reversed to obtain valuable raw materials or elements of the basic structure of the building. The obtained materials are segregated and recovered at high cost. However, there are also risks associated with the cleanliness of materials stored at the recycling centres themselves. Another problem is technical issues. Until now, the main technical problem was the fact that it was difficult to precisely separate the insulating glass units from each other. Until now, this process has been manual. Currently, machine manufacturers, e.g. Hegla New Technology GmbH is working on new, promising and more economical solutions: With the IG2Pieces technology, the company has developed a solution that allows the glass in insulating glass units to be separated precisely and without damage and allows the sealing compound to be removed virtually residue-free and fully automatically. Once the individual panes have been separated, they can be recycled in a “closed loop” at a flat glass plant without any loss of raw material quality.

However, to achieve the desired effect, demolition companies will in future have to carefully cut out window panes or glass elements from buildings without breaking them. This requires the creation of new awareness and the implementation of new processes.

The circular economy in the glass industry will be one of the main topics at this year’s glasstec 2024 in Düsseldorf.

| The world’s most important trade fair for the glass industry, glasstec 2024 (International Trade Fair for the Production, Processing and Products of Glass), will take place at the Düsseldorf Exhibition Centre from 22 to 25 October 2024. At glasstec, experts from all over the world can experience the entire range of products and solutions along the entire value chain related to the material glass. The trade fair slogan WE ARE GLASS highlights the importance of the event in the glass industry. This year’s exhibition and accompanying events will focus on topics such as the circular economy, digital technologies and decarbonisation. The glasstec trade fair has been held in Düsseldorf for 25 years on a biennial basis. More info on page: www.glasstec.de |

We encourage you to read the expert article “Circular Economy in the Flat Glass Industry” here